|

COMPASS Ltd. manufactures and sells BEARING ACCESSORIES according to the following standards:

|

|

The ACCESSORIES programme covers:

|

Adapter sleeves |

Withdrawal sleeves |

Locknuts/extraction nuts |

Lock washer |

|

|

|

|

To see parts of our range of manufacturing and mounting dimensions download catalog.

On customer request, can be manufactured other parts than those listed in the catalog, in size modified from the standard dimensions or size in inches.

|

||

|

Adapter sleeves serve to locate bearings with tapered bore on cylindrical shafts. Sleeves mounting permit more relaxed shaft diameter tolerances in contrast to those tolerances where the bearing is directly seated on the shaft. The tolerance classes recommended for shafts are h9 and h10. Form and position deviations will be in accordance with tolerance classes IT5/2, respectively IT7/2. Adapter sleeves are manufactured according to standard ISO 2982-1. The adapter sleeves are supplied complete with locknut and locking device. |

Adapter sleeve Taper 1:12 |

Adapter sleeve Taper 1:12 |

WITHDRAWAL SLEEVES |

||

|

Withdrawal sleeves serve to locate bearings with tapered bore on cylindrical shafts. The bearing rests against a shaft shoulder; the tapered sleeve is pressed into bearing bore until the radial clearance is reduced to the desired amount. For dismounting the bearing, the sleeve is extracted by the extraction nut. The nuts should be ordered separately. Withdrawal sleeves are manufactured according to standard ISO 2982-1. |

Taper 1:12 |

Taper 1:30 |

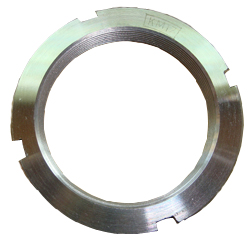

LOCKNUTS / EXTRACTION NUTS |

||

|

Locknuts are used for bearing mounting on adapter sleeves or their dismounting from withdrawal sleeves. Locknuts are manufactured according to standard ISO 2982-2. |

|

HM30, HM31 |

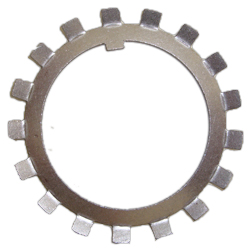

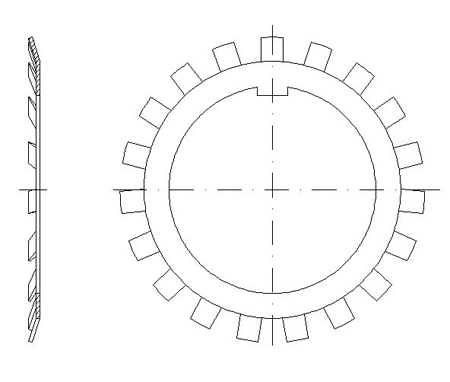

LOCK WASHER |

|

|

Lock washers are used to secure the nuts. Lock washers are manufactured according to standard ISO 2982-2. |

MB, MBL |