|

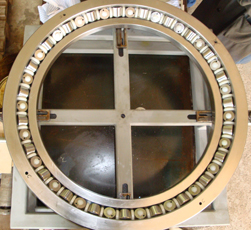

Based on "know-how" gained in decades of work in design and production of bearings, we offer to our customers the reconditioning service of large and special bearings. - crossed tapered roller bearings used for carousel lathes - slewing bearings with external or internal gear used in construction equipment |

|

|

|

Technology of bearings reconditioning: - disassembly and inspection bearing components - evaluation / measurement of the degree of components wear - reconditioning of the inner and outer raceways - bearing internal construction and component redesigning - processing components to be replaced - bearing assembly - final inspection of the bearing assembly - washing-preservation-packaging |

|

|

This service is a good alternative for clients when the cost of refurbishment is substantially lower than the cost of a new bearing or when the delivery time for a new bearing is much longer than needed for reconditioning the bearing.

| 26.06.2019 |

A NEW HIGH PERFORMANCE MACHINE |

| 27.04.2018 |

New investment to increase cutting capacity |